Recycling

General Information

Recycling or recirculation is the reuse of recyclable substances after primary purification (filtration, drying, etc.). In the case of refrigerants, recycling usually involves their return to the equipment. Often such a process takes place „on the spot“ (definition of the 4th Meeting of the Parties to the Montreal Protocol, decision IV/24).

In decision IV/24, recycling is separated from recovery — re-treatment and improvement of the properties of the disposed substance by filtration, drying, distillation and chemical treatment to restore the substance to certain standard characteristics (recovery is often carried out in a specialized center on high-performance equipment, outside the place of refrigeration system’s operation).

At the same time, Federal Law of the Russian Federation No. 7-FZ of 10.01.2002 „On Environmental Protection“ defines the recycling of ozone-depleting substances as their reuse after recovery. The law calls recovery the treatment of recovered ozone-depleting substances by filtration, drying, distillation, chemical treatment in order to restore consumer properties, without distinguishing between primary purification and re-treatment.

Legislative basis for the recycling of ODS and F-gases

The Montreal Protocol sets limits on the permissible consumption of controlled substances. At the same time, consumption is defined as (Production + Imports—Exports). The Montreal Protocol considers production to be the amount of controlled substances produced minus the amount of substances destroyed, as well as the amount of substances used exclusively as raw materials. The amount of substances that have been recycled and reused is not considered as production (Article 1, paragraph 5,6).

The import and export of recycled and used controlled substances should not be taken into account when calculating consumption (Decision IV/24, paragraph 2).

This means that the recycling of old refrigerants pumped out of the equipment contribute to the creation a legal stock of refrigerants being withdrawn from circulation. The volume of that stock will not be limited by the consumption limits established by the Montreal Protocol.

Accounting and reporting in respect of produced, used, stored, recovered, recycled and destroyed ozone-depleting substances is carried out in accordance with the procedure established by the Decree of the Government of the Russian Federation dated 18.02.2022 No.206 „On measures of state regulation of consumption and circulation of substances that destroy the ozone layer“.

Requirements for the extraction, reuse and disposal of refrigerant are contained in GOST 32968-2014 „Refrigeration equipment. Refrigerants. Requirements for use and recovery“.

Methods of extraction and recovery of refrigerants

The State Standard of the Russian Federation GOST 32968-2014 prescribes to extract, reuse and dispose of refrigerant in accordance with paragraphs 6.1.4, 6.1.5, 6.2, 6.3 and 6.5 of GOST EN 378-4 „Refrigeration systems and heat pumps. Safety and environmental requirements. Part 4. Operation, maintenance, repair and restoration“.

The extraction of the refrigerant, its recovery, preparation for reuse and disposal should be carried out only by trained personnel with appropriate knowledge and experience.

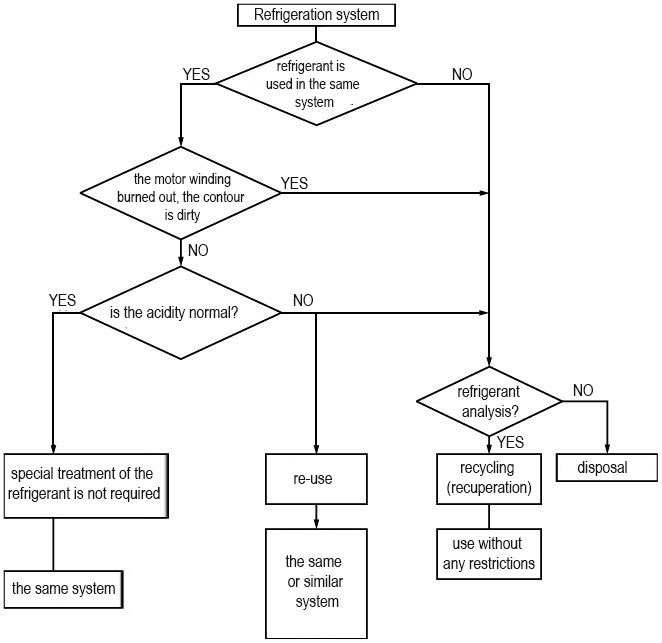

The refrigerant and oil extracted from the system, after extraction, are to be sent for disposal (destruction), or for reuse.

Before pumping out the refrigerant from the refrigeration system, its condition is determined based on the following information:

- the background of the operation of the refrigeration system;

- type and placement of the refrigerant in the refrigeration system;

- the grounds on which the refrigerant is to be removed from the refrigeration system;

- the technical condition of the refrigeration system or equipment as a whole, as well as whether it will be operated in the future or not.

Refrigerants intended for reuse are subjected to recovery in order to achieve characteristics corresponding to the characteristics of new refrigerants that have not been in operation.

When recovering halogen-containing hydrocarbons, the following checks are performed:

- Checking the acidity by titration

When checking the acidity for analysis, a sample weighing 100—120 grams is takenю The lower limit of the sensitivity of the test to determine the acid content should be no more than 10-7 fractions by weight (in terms of hydrochloric acid HCI). If the acid content exceeds the maximum permissible level, then all the extracted refrigerant is sent for recovery (purification), and the filters-dryers in the refrigeration system are replaced. - Moisture testing by coulometric titration according to Karl Fischer

To conduct an analysis for the presence of water, a sample (for any refrigerants) must be taken in the liquid phase in an appropriate container for research. If the moisture content of the refrigerant is higher than the maximum permissible, then all the extracted refrigerant is sent for recovery (purification), and the filters-dryers in the refrigeration system are replaced.

Equipment for the pumping out and purification of refrigerants must comply with the requirements of the State Standard of the Russian Federation GOST ISO 11650-2017 „Equipment for the recovery and/or reuse of refrigerant. Operational characteristics“, and for refrigerants based on halogenated hydrocarbons – and the requirements of GOST IEC 60335-2-104-2013 „Household and similar electrical appliances. Safety. Part 2-104. Additional requirements for devices designed for the recovery and/or recirculation of refrigerants in air conditioning equipment and refrigeration equipment“.

Procedure for the extraction and collection of refrigerant:

- If the compressor of the refrigeration system cannot be used for the extraction and collection of refrigerant, connect the equipment for the extraction and collection of refrigerant in another part of the refrigeration system or in a separate container;

Note: Equipment for the extraction of refrigerants is usually an aggregate consisting of a compressor, an oil separator, a condenser and auxiliary elements. The equipment may contain filters-dryers and anti-acid filters with replaceable cartridges in order to remove moisture, acid, mechanical particles and other contaminants. - Before depressurization of the refrigeration circuit, the pressure in the refrigeration system or its corresponding part is lowered to a value of no more than 30 kPa (absolute pressure).

- Before disposal, the refrigeration system or its elements are evacuated to a residual pressure in them of no more than 30 kPa (absolute pressure).

Note: The above pressure values correspond to an ambient temperature of 20°C. For other temperature values, the pressure values must be adjusted. The duration of refrigerant pumping-out or vacuuming the system depends on the pressure. Refrigerant extraction and vacuuming can be stopped when the pressure in the circuit remains constant after the pump compressor is turned off.

The refrigerant should be collected only in a special container designed for that particular refrigerant. This container must be marked with a color code or in another way that makes it easy to identify the contents of the container as provided for the refrigerant in question. The container for recovered refrigerants must have a special marking.

The use of disposable throwaway containers is not allowed due to the possibility of gas residues from the container entering the atmosphere.

All operations for the extraction and recovery of refrigerants, as well as the exact reasons for performing these operations, are to be recorded in the Journal of the technical condition of the refrigeration system.