Ammonia + carbon dioxide (NH3 + CO2)

Cascade refrigeration plants with ammonia (NH3, R-717) as a refrigerant in the high-temperature cascade and carbon dioxide (CO2, R-744) as a refrigerant in the low-temperature cascade or a secondary refrigerant (brine):

- maintain optimum temperature conditions for each refrigerant;

- enhance safety due to significantly reduced ammonia charge as compared to only-ammonia systems of the same capacity;

- have smaller size and material content due to miniaturization of cooling devices and diameter of suction lines of a CO2 circuit as compared to only-ammonia systems of the same capacity.

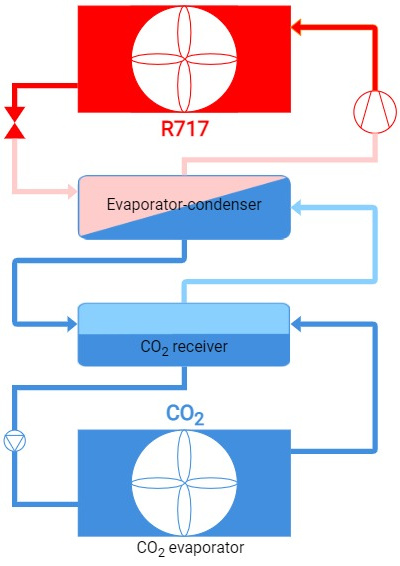

Ammonia refrigeration plant with CO2 as a secondary refrigerant

Refrigeration systems with the refrigerant ammonia that cools the secondary refrigerant liquid CO2 can be used for freezing, low-, medium- and high-temperature storage.

In heat exchangers of refrigeration users, CO2 not only warms through removing the heat of a cooled body or environment but partly evaporates which improves the efficiency of refrigeration and makes it possible to downsize components, fitting, and pipes.

Below is the scheme of such a plant:

CO2 is cooled in a cascade heat exchanger that acts as an evaporator for an ammonia circuit and a condenser for a CO2 circuit, enters the receiver and then is pumped to a user’s heat exchanger (evaporator). The liquid secondary refrigerant is returned to the receiver, and the gaseous one is fed into the cascade cooler for condensation.

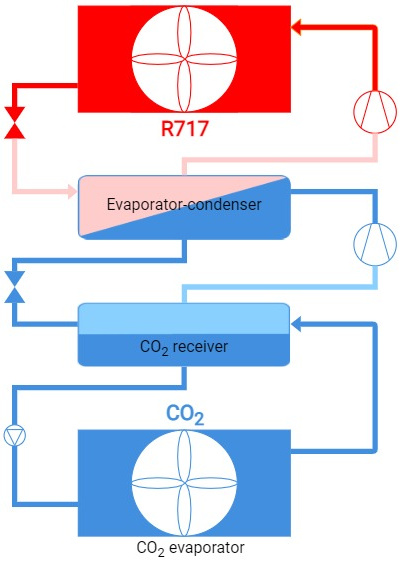

NH3/CO2 cascade refrigeration plant

A cascade system with CO2 as a phase-change refrigerant on the low-pressure side with NH3 on the high-pressure side is presented in the figure below:

The liquid CO2 is pumped from the receiver to a user’s heat exchanger (evaporator). Partially evaporated liquid CO2 returns then to the receiver, and gaseous CO2 is compressed in the compressor, and condensed in the cascade heat exchanger acting as an evaporator of the ammonia circuit.

As compared to an only-ammonia system, the ammonia charge in a cascade system can be 10 times less.

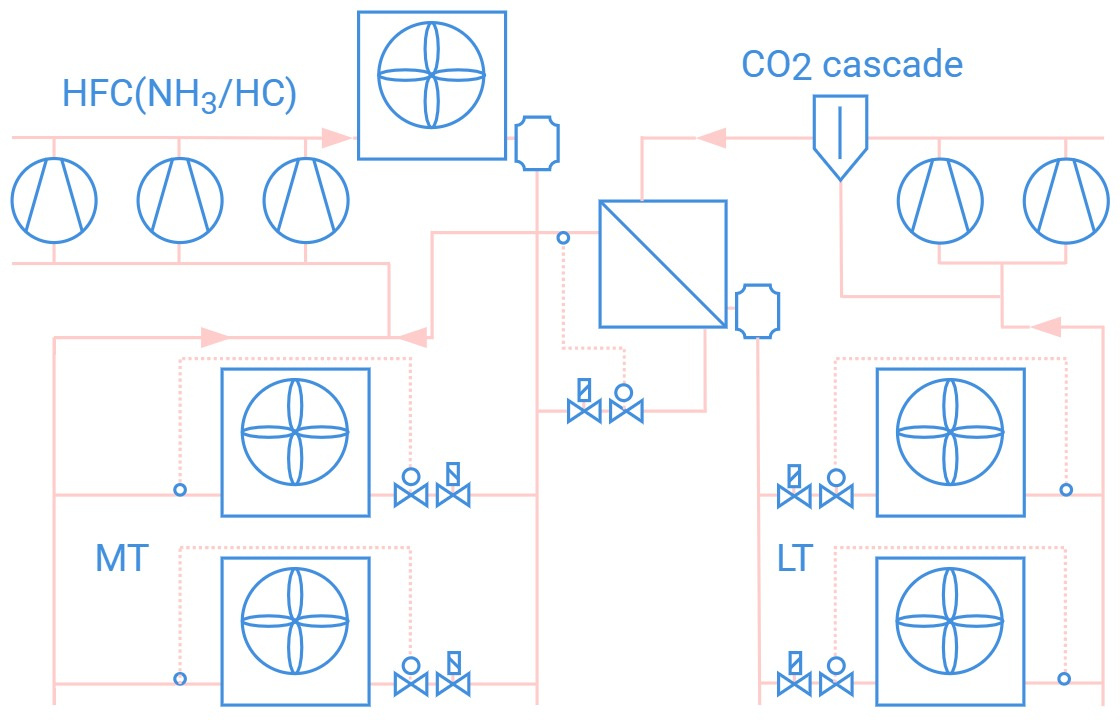

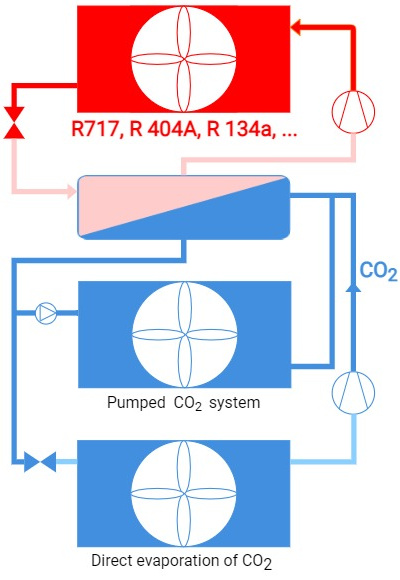

Hybrid systems

Cascade system can combine different technologies: direct evaporation, pump circulation, secondary refrigerant.

Below are solutions that allow refrigeration at several temperature levels.

The first figure shows a system with the CO2 circuit—supplying low-temperature users—connected to the traditional refrigerating plant (that can use NH3)—supplying medium-temperature users—via the cascade heat exchanger.

The second figure shows a hybrid system with pumped CO2 for medium-temperature users, and direct evaporation of CO2 with the following compression of its vapors by the compressor for low-temperature users.

Additional materials

- Automated cold-storage facility in Canada to employ integrated CO2 system

- Refrigerant Carbon Credits Plan Aims at Cutting Cost of NatRef Transition

- GEA Refrigeration Technologies: control the cold at sea (in Russian)

- Energy and environmental paradigms of refrigerants (in Russian)

- Refrigerants and environment (in Russian)

- Natural refrigerants in North America. Industry and special uses (in Russian)

- Brazilian supermarkets choose CO2 (in Russian)

- Latest Japan, Chinese, and Australian NH3/CO2 systems at ATMOsphere Asia 2014 (in Russian)

- Natural refrigerants in North America. Food supply (in Russian)

- Natural refrigerants come to commercial refrigeration (in Russian)

- Carbon dioxide needs ammonia (in Russian)

- Ammonia refrigeration plants in China (in Russian)

- Use of ammonia in Africa, Thailand, China. Bangkok conference results (in Russian)

- IIAR 2014: CO2 triumph in Brazil (in Russian)

- Trends in the development of ammonia refrigeration systems (in Russian)

- United States Cold Storage invests in NH3/CO2 cascade systems (in Russian)