Small grants programme

Background

The survey held under Phase 1 revealed that ODSs and F-gases used in refrigeration equipment of vessels, onshore and servicing enterprises of the fishing industry of the Murmansk oblast are equal to 32.48 ODP t and 1,000,843.59 t CO2-eq.

The average leakage amount is as follows:

| Total | Onshore enterprises | Vessels | Servicing sector | |

|---|---|---|---|---|

| ODP t | 3.98 | 0.79 | 2.96 | 0.23 |

| t CO2-eq. | 117,557.56 | 24,669.13 | 86,120.77 | 6,767.67 |

The survey showed that combustion of diesel and fuel oil to maintain the operation of refrigeration equipment of vessels generates 201,190.73 t CO2-eq. in greenhouse gas emissions.

Component activities

The planned component activities are:

- converting several small and medium enterprises of the fishing industry of the Murmansk oblast to ozone- and climate-safe low GWP substances and technologies;

- supporting the Murmansk oblast servicing sector in transfer to environmentally safe alternatives (provision of servicing tools to install, repair, and service refrigeration equipment and handling alternative refrigerants in an environmentally safe manner and training of personnel);

- activities aimed at reduction of ODS and F-gas leakages and improvement of energy efficiency at the selected vessels and onshore enterprises of the fishing industry of the Murmansk oblast;

- training and workshops dedicated to:

- leakage reduction and energy audit using modern instrumentation, and compilation of the list of low-cost and cost-neutral technical arrangements;

- familiarization of representatives of the fishing industry with the results of the conversion and technical audit;

- current international and national legislation on energy saving and improvement of energy efficiency of refrigeration equipment, including interim testing and practice.

The assistance under the small grants programme will receive:

- LLC Ref-Technologies,

- LLC Klimat i Komfort,

- LLC Ref-Master,

- LLC SPS-Kholod-Murmansk,

- LLC Pelaghika,

- LLC TD Samson-trade.

Outcomes of the Project

1. The refrigeration warehouse of TD Samson-Trade Ltd, which previously used ozone-depleting refrigerant R-22 and hydrofluorocarbon R-134a, was converted to natural refrigerants in July 2022. The warehouse consists of four cold storage rooms for long-term storage of frozen fish and seafood products at a temperature of -18 …-25°C.

As part of the conversion, design and estimate documentation was developed, primary and extra equipment was supplied, installation and commissioning works were carried out, old equipment was dismantled and properly disposed, and old refrigerants were recovered and recycled. The personnel of TD Samson-Trade Ltd was trained. As a result, not only ozone-depleting substances and F-gases were phased out, but also energy efficiency of the system has increased by 25%.

In the course of the work, the contractor—Nord-SM LLC—trained a local company, Ref–Technologii LLC, in the installation and maintenance of carbon dioxide refrigeration systems.

For educational purposes, the facility is actively visited by local customers and service companies of Murmansk, as well as students of profile universities of Murmansk oblast, for practical consolidation of skills in the use of carbon dioxide refrigeration systems.

2. Tools and equipment for environmentally friendly installation, repair and maintenance of refrigeration systems, for working with alternative refrigerant were provided to service companies of the Murmansk oblast in September 2021. Among the transferred equipment: express analyzers and refrigerant evacuation stations, portable thermal imagers, leak detectors and a number of other tools and devices.

The supplied equipment allows specialists of service companies to:

- Determine the type of refrigerant at the customer’s facilities for refilling;

- Recover refrigerants for further recycling;

- Recycle small amounts of refrigerants;

- Improve the efficiency of works with the refrigeration circuits;

- Work with new alternative refrigerants.

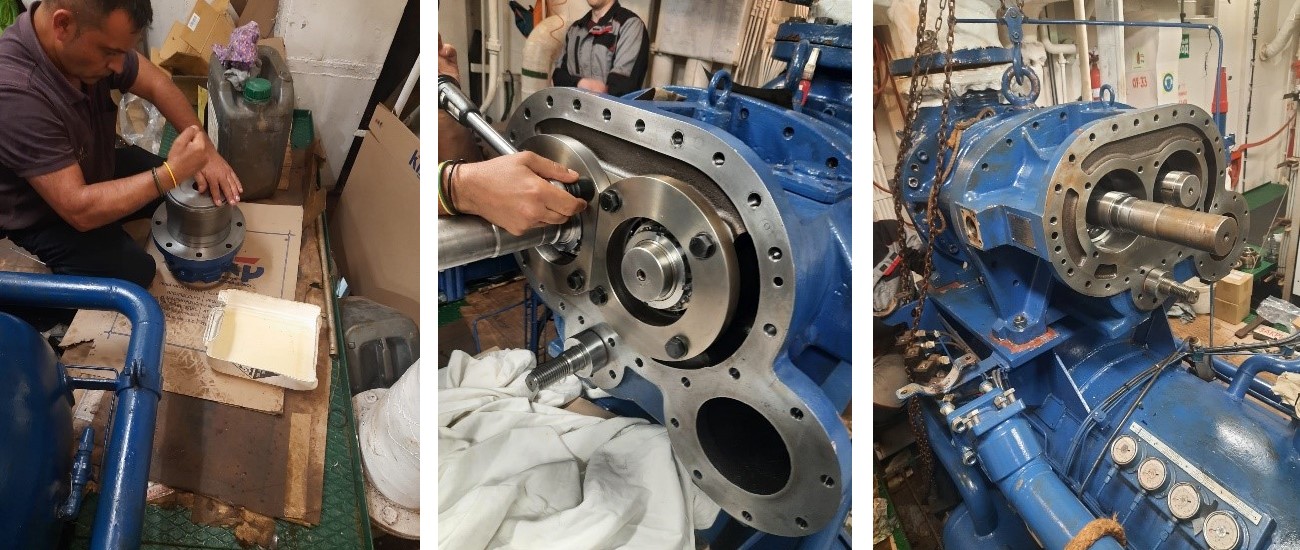

3. Leaks of ozone-depleting refrigerant R-22 on the fishing vessel, owned by Pelagika LLC, have been significantly reduced. This freezer-canning fishing trawler (super-trawler) AK-0749 Karelia of the „MoonZund“ type (Atlantic-488 project) was built in Germany in the early 90s. By the time the Project was launched, the vessel’s refrigeration system was significantly worn out and leaked about 700 kg of ozone-depleting refrigerant R-22 per year. The conversion of the vessel to the natural refrigerants was impractical The conversion of the vessel was impractical due to its 30-year age and, accordingly, a limited remaining service life.

To reduce leaks, a set of spare parts and equipment was purchased, delivered to the ship in July 2022, and installed by December 2022. The installation was carried out by specialists of Pelagika LLC as part of beneficiary co-financing. After the work was completed, the leaks of R-22 practically stopped.

4. Training of service companies in the Murmansk oblast (15 specialists), customers of refrigeration systems, students of MSTU and representatives of government departments of the Murmansk oblast (about 50 people) has been organized.

Trainings were held on legislation in the field of protection of the ozone layer and the Earth’s climate; on refrigerant recovery&recycling systems and environmentally friendly handling of them; on the design, installation and maintenance of refrigeration systems using natural refrigerants; on improving the energy efficiency of refrigeration systems. Qualified experts with deep knowledge and extensive practical experience in the relevant subjects were invited to conduct trainings.

In June—September 2022, 15 specialists of service companies underwent in-depth 3-month professional trainings with the passing of final exams and obtaining certificates confirming permits for:

- work with pressure vessels (maintenance of vessels operating under an excess pressure of more than 0.07 MPa (0.7 kgf/sq.cm);

- work at height (group 1);

- soldering and tinning works (soldering and tinning of products; storage, transportation and operation of cylinders (oxygen, acetylene, liquefied petroleum gases) and portable gas burners;

- electrical installation works and fire-technical minimum (safety qualification) (group 2, up to 1000 volts).

As a result, specialists were able to legally and professionally work not only with the HFC, but also with eco-friendly natural refrigerants, further spreading the experience of the project.

Links