Industrial Refrigeration System Market - Global Forecast to 2026

October 20, 2021

The global industrial refrigeration system market is estimated to grow from USD 19.4 billion in 2021 to USD 25.1 billion by 2026 at a CAGR of 5.3% during 2021–2026. The growth of the industrial refrigeration system market is driven by factors such as the rising demand for innovative and compact refrigeration systems; increasing government support to strengthen cold chain infrastructure in developing countries; and growing inclination toward eco-friendly refrigerant-based refrigeration systems due to stringent regulatory policies.

COVID-19 Impact on the Global Industrial Refrigeration System Market

The industrial refrigeration system market includes key companies such as Johnson Controls (Ireland), Emerson Electric Co. (US), GEA Group Aktiengesellschaft (Germany), Danfoss (Denmark), Mayekawa (Japan), Daikin (Japan), Ingersoll Rand (Ireland), EVAPCO, Inc. (US), Baltimore Aircoil Company (US), BITZER (Germany), and LU-VE Group (Italy). These companies have their manufacturing facilities and corporate offices spread across various countries across Asia Pacific, Europe, North America, and Rows. The industrial refrigeration components manufactured by these companies are purchased by several stakeholders for various end use. COVID-19 has impacted the operations of the various industrial refrigeration manufacturers companies, along with businesses of their suppliers and distributors. The fall in export shipments, delay in projects, and slow domestic demand industrial refrigeration system in comparison to pre COVID-19 levels is also expected to negatively impact and slightly stagnate the demand for the industrial refrigeration system market in short term.

Industrial Refrigeration System Market Dynamics

Driver: Increasing government support to strengthen cold chain infrastructure in developing countries

In developing countries, food wastage is one of the primary reasons for the shortage of food. India is among the leading producers of food products and other perishable goods, including milk products, fruits, and vegetables. However, each year, food products worth billions of dollars get wasted due to the lack of proper cold chain infrastructure, including collection centers, refrigerated transport, pack houses, and cold storage facilities, which are required to keep food products fresh and safe. Thus, the lack of efficient cold chain infrastructure is the primary cause of food wastage and food loss. The shelf life of fruits, vegetables, fish, and dairy products decreases dramatically due to factors such as improper handling, insufficient infrastructure, no access to cold chains, a dearth of energy resources to power these cold chain facilities, and so on. Therefore, many developing countries, such as China and India, have started adopting advanced refrigeration systems across cold storage and cold chain infrastructure to ensure uninterrupted temperature-controlled transport and storage of perishable food products, beverages, chemicals, medicines, and pharmaceuticals, among others.

In China, strong government initiatives toward developing and improving cold storage warehouses and refrigerated transportation systems, especially in major cities such as Shanghai and Beijing, are driving the industrial refrigeration system market growth. The growing middle-class population in these countries and its rising demand for better and fresher products are the other major factors that create the need to upgrade the cold chain infrastructure utilizing advanced technologies and implementing better regulations.

Restraint: High installation cost and other expenses

Industrial refrigeration systems typically have a high installation cost owing to the high cost of their components, such as compressors, condensers, and evaporators. Also, the control systems used in these refrigeration systems are expensive, which increases the installation cost. Furthermore, refrigerants such as ammonia and certain hydrocarbons are flammable and corrosive. Similarly, exposure to high concentrations of ammonia is toxic and life-threatening if inhaled. Therefore, safety equipment is required when working with ammonia-based refrigeration systems. Ammonia-based refrigeration systems should be made of high-cost materials such as steel and aluminum because ammonia reacts with and corrodes copper, which increases the overall initial cost of the system. Also, while working on CO2-based refrigeration systems, safety equipment should be installed to avoid leakage as it may cause serious health hazards and suffocation. Along with the installation cost, other expenses such as regular maintenance, staff training, and the high cost of energy also increase the overall operational costs, thereby restraining the market growth.

Opportunity: Growing popularity of carbon dioxide/ammonia (CO2/NH3)-based cascade refrigeration systems

Over the past few years, natural refrigerant-based systems have gained traction to overcome the environmental problems related to global warming and the depletion of the ozone layer caused by synthetic refrigerants. Ammonia and carbon dioxide as refrigerants are simple to use, cost-effective, and available in abundance. Carbon dioxide/ammonia-based cascade refrigeration systems are used in low-temperature applications and are suitable for industrial applications where the required temperature for a product range from -30°C to -50°C. These systems vary in capacity, between 25 and 1,500 tons for applications such as process plate freezers, spiral freezers, refrigerated warehouses, and blast freezers. A cascade system generally comprises two separate one-stage refrigeration cycles, each working with a different refrigerant. Such systems are best suited for applications in which the difference between heat rejection temperature and refrigeration temperature is so drastic that a single refrigerant with suitable properties cannot be found. In CO2/NH3-based cascade refrigeration systems, CO2 refrigerant is used in low-temperature circuits, and ammonia refrigerant is used in high-temperature circuits.

Challenge: Lack of skilled personnel and safety concerns

Natural refrigerant-based systems have been adopted at a significant rate in recent years. Governments worldwide are promoting the use of environmentally friendly refrigeration systems to reduce the impact of synthetic refrigerant-based systems on global warming and ozone layer depletion. According to the Bureau of Labor Statistics (US), the growth rate for job creation in the industrial refrigeration system ecosystem is projected to be around 13% from 2018–2028, which is much faster than the average growth rate. However, there is a lack of skilled on-site personnel to handle and manage systems effectively and safely. This problem can be addressed by the collaboration of the government, industry, and research institutes to meet the increasing demand for a skilled workforce in the industrial refrigeration system market.

As natural refrigerant-based systems have gained traction, the demand for ammonia and carbon dioxide as refrigerants has gone up significantly. This increase in demand is because these refrigerants have zero ODP and low GWP. For instance, ammonia is a standard refrigerant used in industrial refrigeration facilities worldwide, and it is environmentally friendly and complies with the low-GWP standard. However, ammonia is also regarded as a poisonous gas, and its accidental leakage in facilities can lead to severe industrial accidents. Furthermore, exposure to lower concentrations of ammonia can lead to temporary blindness, eye damage, skin diseases, or pulmonary diseases, while exposure to higher concentration levels can be fatal. Also, the inner leakage of such gases can even contaminate food items kept inside the refrigeration system. Hence, the lack of skilled personnel and safety concerns act as major challenges for the growth of the industrial refrigeration system market.

Controls to register higher CAGR during the forecast period

The controls segment is projected to register the higher CAGR during the forecast period, by component. Controls of the industrial refrigeration system market is projected to register the highest CAGR during the forecast period, by component. The use of controls in an industrial refrigeration system ensures increased efficiency, can automate temperature controls, and makes requirement-based adjustments. Also, control systems can be used to automate defrost cycles at different times, resulting in significant energy savings. Furthermore, companies are heavily investing in R&D activities to enhance the efficiency of industrial systems and reduce operational costs, which are expected to drive the market for controls during the forecast period.

CO2-based refrigeration systems for microgrid hardware segment is expected to witness higher CAGR growth during the forecast period

The market for CO2-based refrigeration systems is expected to grow at the highest CAGR of 7.5% during the forecast period. The key factor for the market’s growth is the rising popularity of CO2 cascade refrigeration systems in various applications. CO2 is abundant and stays in the atmosphere for a longer time. Large CO2-based industrial refrigeration systems are less expensive to build than their glycol counterparts; thus, the initial and life cycle costs of CO2-based industrial refrigeration systems are comparatively low. Additionally, CO2 has other beneficial characteristics, such as no toxicity, no flammability, high heat transfer, high refrigeration volumetric capacity, and negligible GWP. It is also environmentally safe, benign, and non-corrosive with most materials, thereby providing lucrative opportunities for use in the CO2-based refrigeration system market. Moreover, all these advantages, coupled with increasing awareness about the thermodynamic properties of CO2 refrigerants, are expected to propel the market for CO2-based refrigeration systems.

The chemical, petrochemical, and pharmaceutical segment for the industrial refrigeration system market is expected to witness higher CAGR growth during the forecast period

The industrial refrigeration system market for chemical, petrochemical, and pharmaceutical applications is expected to grow at the highest CAGR during the forecast period. Processes in chemicals and petrochemicals industries, particularly handling and processing substances such as oil, gas, and other chemical compounds, are extremely challenging. Different processes and operations in these applications require the removal of heat and refrigeration to produce the final product. These processes include crystallization or condensation. Similarly, the pharmaceutical industry relies on refrigerated or temperature-controlled systems to preserve and maintain the integrity of products. A key factor for the growth in chemical, petrochemical, and pharmaceutical applications is the increasing demand for industrial cold storage facilities to store medicines and vaccines. Additionally, running clinical testing and research to halt the outbreak of the COVID-19 pandemic across North America and APAC is also driving the market growth.

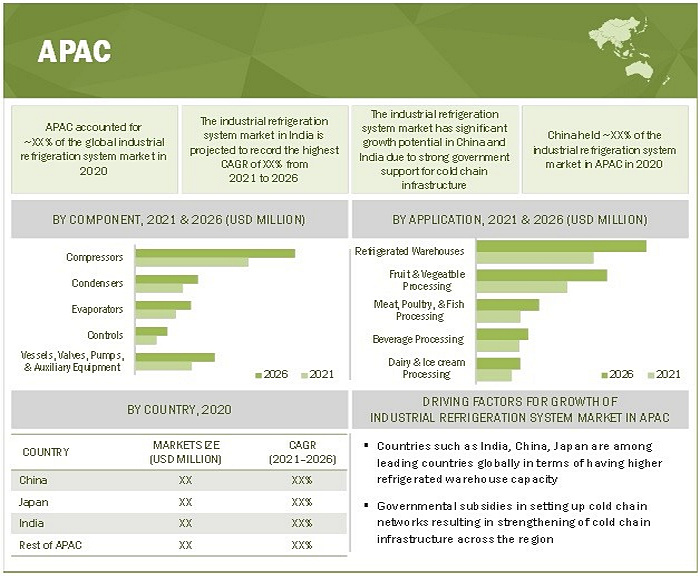

APAC is projected to register the highest CAGR growth during the forecast period

APAC is likely to be the fastest-growing industrial refrigeration systems market during the forecast period. The market’s growth can be attributed to the growing pharmaceutical industry in the region, coupled with government subsidies for improving the cold chain and preservation infrastructure. Refrigerated storage capacities are growing in APAC countries such as India, China, and Japan. Moreover, governments of various countries in APAC support the Montreal Protocol initiative to phase out environmentally harmful refrigerants, thereby providing huge opportunities for the players offering natural refrigerant-based refrigeration systems. Thus, government initiatives to further strengthen cold chain management systems are expected to be the key driver for the growth of industrial refrigeration systems in the APAC region.

Key Market Players

The industrial refrigeration system market is dominated by a few established players such as Johnson Controls (Ireland), Emerson Electric Co. (US), GEA Group Aktiengesellschaft (Germany), Danfoss (Denmark), and Mayekawa (Japan).