Study finds ‘novel’ transcritical CO2 ejector system outperforms conventional CO2 system up to 82.5% in hot climate

June 02, 2023

A “novel” transcritical CO2 (R744) supermarket refrigeration system using a multi-ejector, parallel compression and mechanical subcooling was found in a new study to be up to 82.5% more efficient than a conventional transcritical CO2 booster system in a warm ambient climate.

That was the message from Mani Sankar Dasgupta, a professor at BITS (Birla Institute of Science and Technology) in Pilani, India, who presented his research paper “A novel IMS-ejector based supermarket CO2 refrigeration system for the extended south of CO2 equator” at the 10th International Institute of Refrigeration (IIR) conference, held in Ohrid, North Macedonia, April 27–29.

“The efficiency of this novel system was found [to be] up to 82.5% [better] in hot climates as compared to the conventional booster system,” said Dasgupta.

According to the study, in the ambient range of 30 to 40°C (86 to 96°F), the efficiency of the proposed system was also found to be superior by 18.7–46.8% over the R404A-based DX system; by 13.85–50.4% over a transcritical CO2 system with parallel compression and flooded medium-temperature (MT) evaporators; by 34.85–56.7% over a transcritical CO2 system with just parallel compression; and by 41.4–82.5% over a conventional transcritical CO2 booster system.

Dasgupta noted that the novel system’s efficiency increased with higher ambient temperatures, but the gain was affected by whether or not flooded evaporators were used. The COP of the proposed multi-ejector system using flooded MT and low-temperature (LT) evaporators was found to increase from 0.95–15% with an increase in ambient temperature from 30 to 40°C (86 to 96°F). The system that did not use flooded evaporators showed an increase in COP from 6.22–22.8% in the same temperature range.

The study also investigated the effect of the “pseudocritical point” on the performance of each component in the novel system. At the pseudocritical point of CO2, the pressure is 80bar (1,160psi) and about 34.5°C (94°F); the critical point is slightly lower, at 74 bar (1,070psi) and 31°C (88°F).

The novel system’s configuration

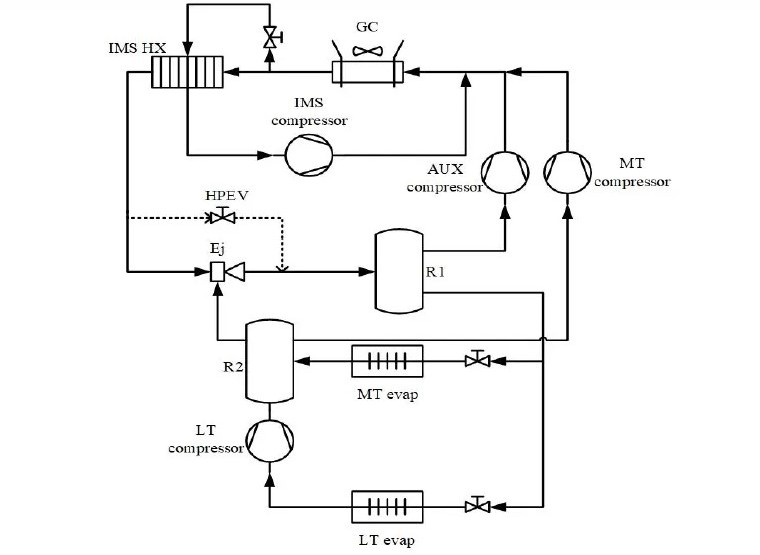

Schematic of the IMS – ejector based CO2 refrigeration system

Schematic of the IMS – ejector based CO2 refrigeration system

The proposed configuration for the new transcritical CO2 ejector refrigeration system is specifically designed for supermarkets in warm climates.

The system’s LT and MT evaporator display cabinets have an assumed cooling load of 25kW (7.1TR) and 120kW (34.12TR), respectively.

The low-stage LT compressor, a BITZER 2GSL-3K model, matches the pressure of the MT evaporator. The combined refrigerant flow from the MT evaporator and LT compressor is handled by a medium-stage MT compressor, a DORIN CD-380H model, and an ejector, the Danfoss HP 1875 model, which can generate pressure lifts to 11bar (160psi). The load distribution between the MT compressor and the ejector is 80% and 20%, respectively.

At ambient temperatures below 20°C (68°F), a high-pressure expansion valve (HPEV) and the MT compressor handle the entire load due to reduced energy benefits from the ejector. At temperatures above 20°C, the ejector controls high-side pressures.

Flash gas from the liquid receiver is pressurized to gas cooler pressure via an auxiliary (parallel) compressor, the Frascold D3-1.9TK model, which runs parallel to the MT compressor. The auxiliary compressor operates only when there is enough flash gas in the receiver; it has a variable frequency range of 30–80Hz.

The system also includes an integrated heat exchanger (IMS HX) downstream of the gas cooler (GC) to further cool the refrigerant. A portion of refrigerant is expanded to a pressure corresponding to a 20°C saturated temperature, which is the lower limit due to currently available commercial compressor constraints. This expanded refrigerant stream cools down the refrigerant exiting the gas cooler and subsequently evaporates inside the IMS HX. The vapor at the exit of IMS HX is managed by the IMS compressor, a variable frequency model chosen for its adaptability to various operating conditions.