Mayekawa ammonia-pentane cascade heat pump will heat steam to 145°C for prawn producer Stella Polaris

June 20, 2024

Japanese OEM Mayekawa is developing an ammonia/pentane (R717/R601) cascade system for heat pumps that will produce steam at 145°C (293°F) for Norwegian prawn producer Stella Polaris.

The new heat pump system utilizes a unique cascade setup that features ammonia and pentane heat pumps. This configuration allows for effective heat recovery from the existing cooling system, which is then used to produce steam for prawn cooking. The Stella Polaris facility, located in Finnsnes, Norway, produces around 15,000 metric tons of frozen, cooked and peeled prawns annually.

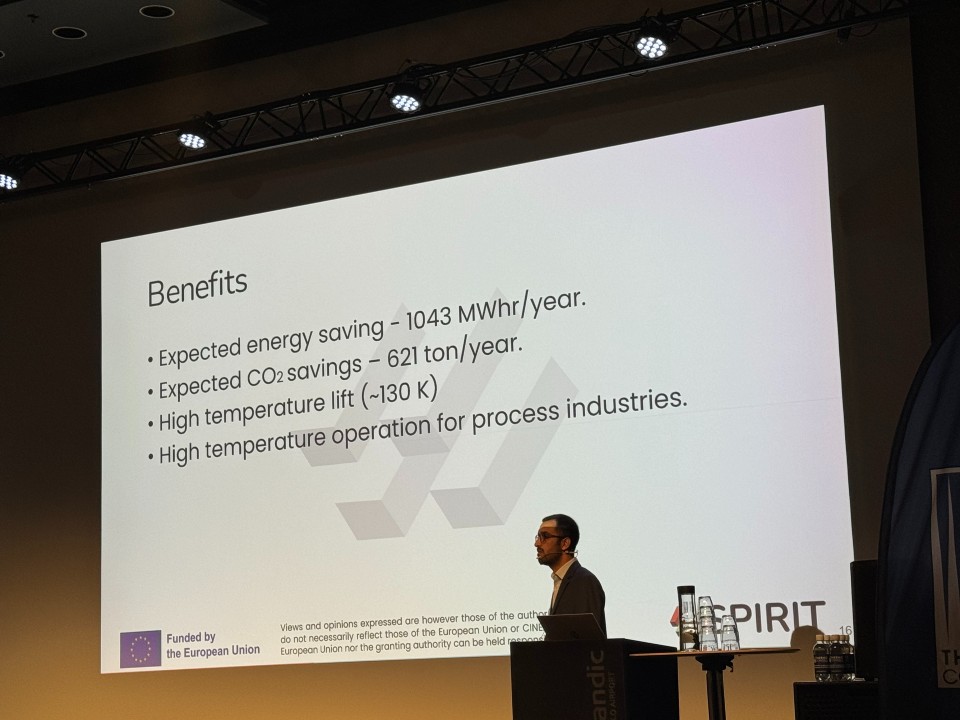

“The new heat pump technology aims to reduce the carbon footprint by nearly a quarter compared to the previous propane [R290] boiler system,” said Faraz Neakakhtar, Project Engineer at Mayekawa. “By recovering waste heat that would otherwise be lost to the environment, we can conserve energy and reduce greenhouse gas emissions by 621 metric tons of CO2e/year.”

Currently, Stella Polaris freezes prawns using a system that rejects heat into the sea. To cook them, the facility utilizes a propane boiler system, which consumes about 9,000MWh of energy annually and produces 2,600 metric tons of CO2e per year.

“In addition to the environmental benefits, the expected energy reduction is projected at 1,043MWh, increasing the energy savings of the new system,” Neakakhtar added. “Our project seeks to enhance operational efficiency and drastically reduce the carbon footprint of one of Norway’s key prawn producers.”

Neakakhtar presented Mayekawa’s heat pump project for Stella Polaris at the Norwegian Refrigeration Technical Meeting 2024 (NKM 2024), held April 10–11 in Oslo.

Mayekawa’s heat pump is being developed as part of the SPIRIT-Heat project, funded by the European Union in collaboration with the Netherlands Organization for Applied Scientific Research (TNO) and Mayekawa. The SPIRIT-Heat Project, funded by the European Commission’s Horizon Europe program, focuses on “sustainable heat-upgrade technologies” for industry.

System design

The ammonia cycle is a lower stage in the cascade system and primarily enhances heat recovery efficiency from the freezing plant. In this cycle, the system operates by boosting condenser waste heat from 18°C to 82°C (64.4 to 179.6°F). This cycle uses a piston compressor from the HS series and a shell and plate-flooded evaporator.

The pentane cycle handles higher temperature demands between 78°C and 150°C (172.4 and 302°F). This cycle is essential for producing 715kW (203.3TR) of heating capacity and generating steam at 145°C (293°F) at 3.2bar (46.4psi), which is directly used in the prawn cookers. A MYCOM screw compressor is used to manage the thermal energy transfer.

“The ammonia/pentane heat pump system has a worst-case combined COP of 1.78 when operating at 18°C/21°C [64.4°F/69.8°F] on the ammonia cascade heat exchanger and 145°C/150°C [293/302°F] on the steam generator heat exchanger [boiler],” said Neakakhtar. “However, if the system runs at a higher source temperature of 22°C/25°C [71.6/77°F] and a lower boiler temperature of 135°C/140°C [275/284°F], the COP can be over 2.”

Next steps

The ammonia/pentane cascade system will be delivered to Stella Polaris at the end of April 2024, with commissioning scheduled between September and October. The operational team will focus on optimizing the compressor and oil systems for high-temperature operations by the end of 2025 alongside conducting testing to ensure the system’s reliability and effectiveness under part-load operations.

“Our system is not only theoretically and technically sound but also proven in operational environments, which is crucial for wider adoption in the industry,” said Neakakhtar. “We are proud to be at the forefront of this change, pushing boundaries of high-temperature lift and using pentane as a refrigerant for different heating processes.”