Study finds that cascade heat pump using mixtures of R744/R600 and R744/R601 produce COP of 4.5 and hot water above 100°C

June 15, 2023

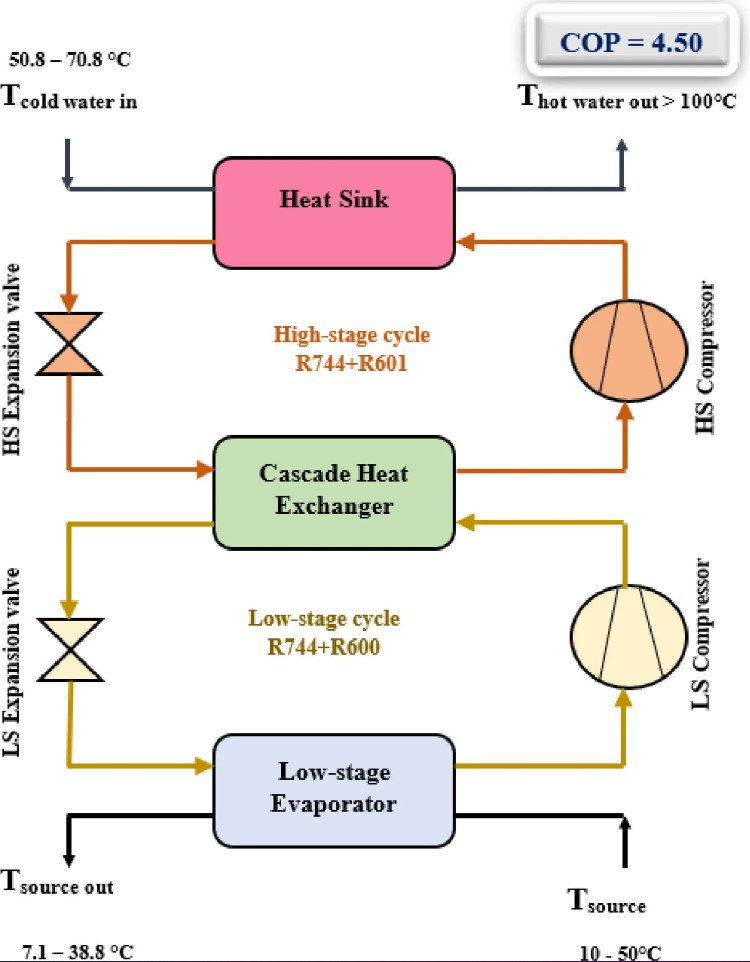

A new study has found that a cascade water-to-water heat pump system employing a mixture of natural refrigerants CO2 and butane (R744 and R600, respectively) in the low stage (LS) and a mixture of CO2 and pentane (R601) at the high stage (HS) can deliver a COP of 4.5 and hot water above 100°C (212°F).

The percentage of CO2 in the mixtures ranged from 2% to 8% by mass.

The study, “Thermodynamic analysis of cascade high-temperature heat pump using natural zeotropic refrigerant mixtures, R744/R600 and R744/R601,” was published in the International Journal of Refrigeration’s May 2023 issue.

The researchers from the Norwegian University of Science and Technology – Ganesan Palanichamy, a Post-Doctoral Researcher, Professor Trygve M. Eikevik and their team – investigated high-temperature heat pump (HTHP) systems, utilizing a two-stage cascade refrigeration system designed to yield hot water at a temperature beyond 100°C and even reaching up to 118°C (244.4°F).

“The system achieved [an average] 36% improvement in the total COP compared to previously published results with this proposed system,” said Ganesan. The previous study used HFO refrigerants R1234ze(E) in the LS and R-1336mzz(Z) in the HS.

The researchers designed and simulated the two-stage cascade HTHP model. The outcomes of this simulation offered insight into the production of hot water at higher temperatures and COP.

Water served as the secondary fluid in both stages. At the LS, it entered the evaporator as a heat source at 10–50°C (50–122°F) and exited at 7.1–38.8°C (44.8–101.8°F). At the HS, it entered the condenser (heat sink) at 50.8–70.8°C (123.4–159.4°F) and exited at more than 100°C.

The cascade system is an amalgamation of two single-stage vapor compression cycles, LS and HS. Connecting the LS with the HS is a cascade heat exchanger, where the hot R744/R600 mixture from the LS is condensed and the cold R744/R601 mixture from the HS is evaporated. The compressed R744/R601 mixture is what ultimately enters the HS heat-sink condenser to heat the water to temperatures above 100°C. (R744/R601 has a higher saturation temperature than R744/R600.) Each of the three heat exchangers follows a counterflow design.

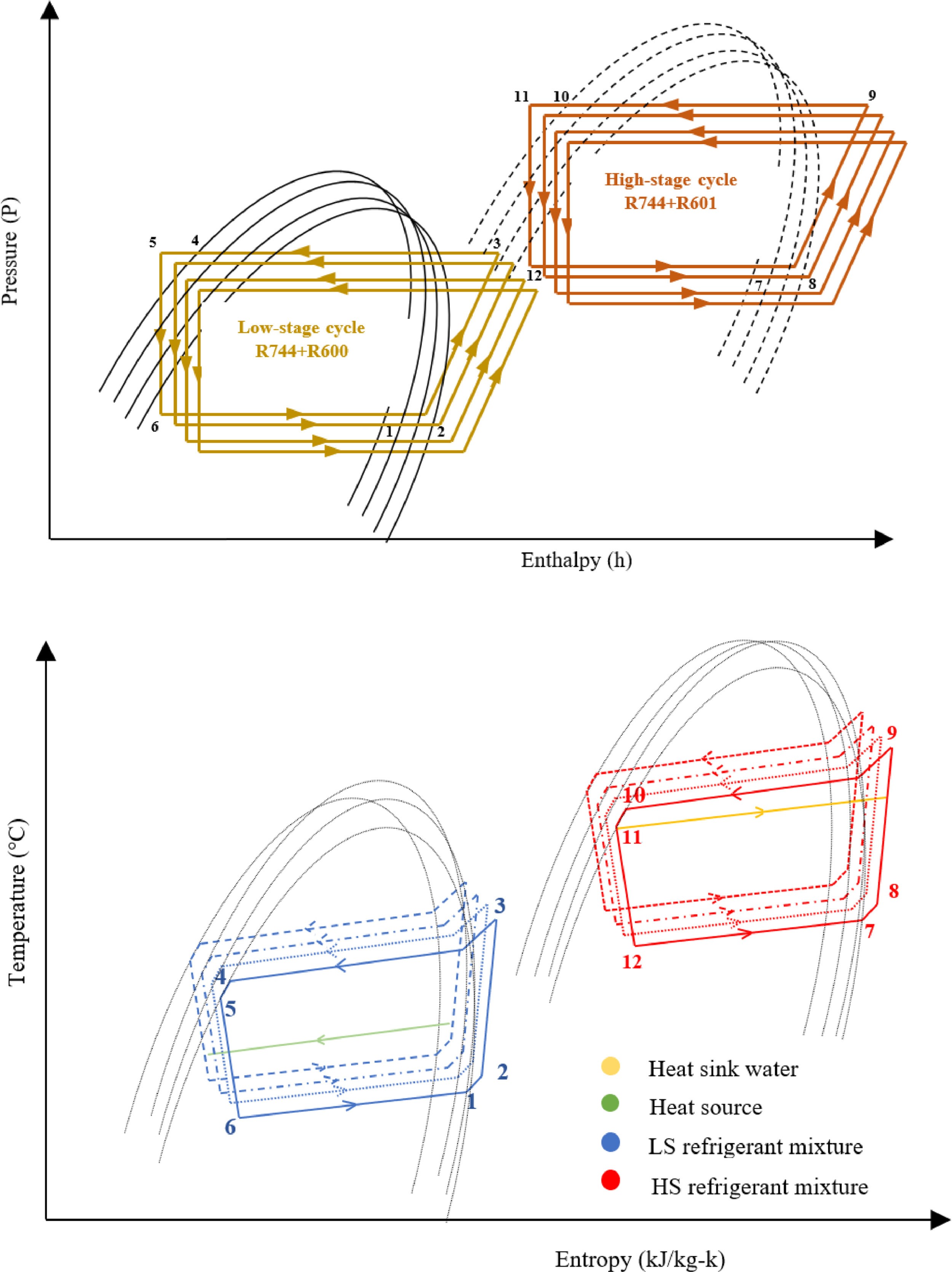

The figure below displays the cascade HTHP system along with pressure-enthalpy diagrams.

Two stage heat pump using natural refrigerant mixture

Two stage heat pump using natural refrigerant mixture

Pressure-Enthalpy and Temperature-Entropy diagram

Pressure-Enthalpy and Temperature-Entropy diagram

In contrast to a single-stage system, the cascade system is adept at managing pressure as it’s split into two stages, facilitating steady-state performance. The pressure ratio is kept low in this system, a feature not shared by single-stage systems. Another pivotal reason for choosing this system is its ability to create a significant temperature lift.

The team examined a range of parameters, including temperature lift, heating capacity, heat sink, and hot water delivery temperatures, as well as COP (HS, LS and total), to assess the performance of the system.

The study findings reflect on the system’s use of natural refrigerants, their high-efficiency performance, and their capability to heat water to high temperatures.

Zeotropic mixtures

R744/R601 and R744/R600 are known as zeotropic mixtures. In these mixtures, condensation and evaporation do not occur at a single, constant temperature, instead taking place over a range of temperatures. Temperature glide is a measure of these differences, indicating the difference between the dew point and bubble point in the evaporation process.

The temperature glides of these mixtures vary in relation to various CO2 mass fractions. As the CO2 mass fraction escalates from 0.01% to 30%, the temperature glide increases, and then it starts to decrease as the CO2 increases from 31% to 100%. By the end, the glide reaches zero when the CO2 reaches 100%. In this study, since the mass fractions of CO2 range from 2% to 8%, the glides are low.

The critical temperature levels for both mixtures are considered. An increase in the CO2 mass fraction results in an increase in the critical temperature for both mixtures. In the study, the mixtures have high critical temperatures.

Thus the study focused on mixtures with low-temperature glide and high critical temperature, striving to strike a balance between system performance and high-temperature heating.

The simulation was formed using four distinct mass fractions in the LS and HS of the system and proved the mixture to be very effective for both cycles. The different mixtures composition used in LS and HS for investigation follow:

Different mixtures composition used in LS and HS

| Refrigerant mixture composition | Low-stage cycle (R744 + R600) | High-stage cycle (R744 + R601) |

|---|---|---|

| 1 | 2% + 98% | 2% + 98% |

| 2 | 4% + 96% | 4% + 96% |

| 3 | 6% + 94% | 6% + 94% |

| 4 | 8% + 92% | 8% + 92% |

Effect of heat source and CO2

The MATLAB computing program was employed to construct and analyze the model comprehensively. The findings of the study led to several conclusions. The heat source temperature profoundly affects the system’s performance, enabling the achievement of high-temperature heating exceeding 100°C.

A comparison of the results from different refrigerant mixture compositions suggests that the system with refrigerant mixture composition 1 (2% CO2) performs optimally, offering high system COP (4.5) and high-temperature heating capabilities above 100°C. As the system became more efficient, it exhibited a heating capacity of 205kW (58.29TR).

Refrigerant mixture composition 2 (4% CO2) could also be employed for superior water heating, though this would cause a drop in the system’s COP. And this trend (higher water temperature, lower COP) continued with compositions 3 and 4, with temperatures reaching 118°C.

The system’s pressure level escalated with an increase in the CO2 mass fraction in the refrigerant mixture but remained comfortably below 2,000kPa (290psi/20bar), enabling the system to operate effectively. The pressure range for both LS and HS of the system were determined to be between 152.5KPa and 1,870kPa (22.11–271.22psi/1.5–18.7bar) and between 115 and 1873kPa (16.67–271.65psi/1.1–18.7bar), respectively.