CTS improves ultra-low-charge ammonia chiller performance with ejector

August 30, 2022

A two-phase ammonia/NH3 (R717) recirculating ejector for liquid overfeed systems can improve the capacity and COP of an ultra-low-charge ammonia chiller by 28% and 22%, respectively, according to Stefan Elbel, CEO of Creative Thermal Solutions (CTS), the Urbana, Illinois (U.S.), HVAC&R research company.

Elbel shared these results during the Technology Trends session at the ATMOsphere (ATMO) America Summit 2022 on natural refrigerants. The conference took place June 7–8 in Alexandria, Virginia, and was organized by ATMOsphere, publisher of Ammonia21.com.

Evaporator overfeed in ammonia systems is often accomplished by means of a motor-driven pump; however, a simpler and more reliable method would be to use a liquid recirculation ejector, explained Elbel. By eliminating the superheat portion of the evaporator, improved capacities and COP can be realized.

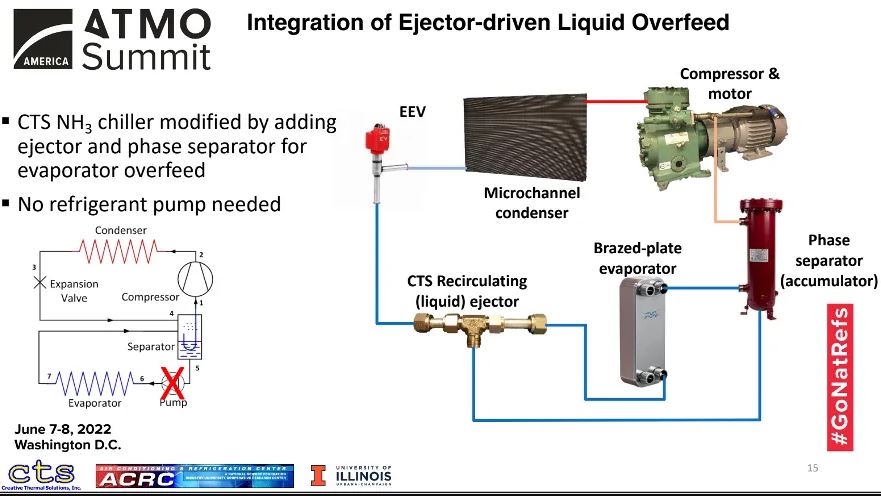

System description showing how to integrate an ejector-driven liquid overfeed

System description showing how to integrate an ejector-driven liquid overfeed

Improving the ultra-low-charge chiller

The ultra-low-charge chiller has a 20kW [68,000 BTU/hr] capacity at AC conditions. Thanks to design improvements, the system has a total system charge of less than 800g (1.75lbs) of ammonia. With 1kg (2.2lbs) of ammonia, 25kW of refrigeration can be achieved (3.25TR/lb). This ultra-low charge is attributed to small line sizes, a custom-designed microchannel condenser and an electronic expansion valve with a nickel-brazed plate evaporator.

CTS modified the chiller by adding a custom-designed recirculating liquid ejector plus a phase separator for the evaporator overfeed. This negated the need for a refrigerant pump, resulting in additional COP improvements.

This liquid ejector overfeed system offers multiple benefits over a traditional dry-expansion (DX) system. For example, it eliminates the risk of dryout and also reduces distribution problems in the system.

When comparing the liquid ejector overfeed system to a DX system, CTS found that the evaporator’s overall heat transfer coefficient (UA) increased between 60 and 200%. This is largely thanks to the reduction in superheat, which improves the overall performance, Elbel explained.

The overfeed system results in a 2–6°C (4–11°F) rise in evaporation temperature. The greatest improvement is at low-capacity or part-load operation of DX systems where generally more superheat is produced.

The remainder of Elbel’s presentation focused on CO2 (R744) technology advances in various applications.