25.11.2015 - 26.11.2015 - Workshop on use of methyl formate as a PU foaming agent

On November 25–26, 2015, Vladimir hosted a workshop on use of methyl formate (MF) as a PU foaming agent.

More than 20 representatives of the foam sector and ICSTI specialists participated in the workshop.

Day 1 was dedicated to the following:

- About UNIDO/GEF-MNRE Project “Phase Out of HCFCs and Promotion of HFC-Free Energy Efficient Refrigeration and Air-Conditioning Systems in the Russian Federation Through Technology Transfer”

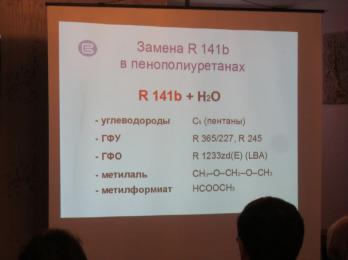

Speaker: E. R. Gommen, representative of the ICSTI’s PMU - Survey of foaming agents

Content: HCFC-141b replacement options and comparison of various foaming agents.

Speaker: E. S. Guseva, manufacturing engineer, NVP Vladipur - MF-based PU systems

Content: MF-based PU systems ready for commercial manufacture of shells, insulated plates, including high density ones.

Speaker: D. A. Potapov, chemical engineer, NVP Vladipur - Use of MF-based PU systems with various types of equipment

Content: Use pattern of MF-based PU systems with various types of equipment.

Speaker: S. V. Samarets, chief engineer, NVP Vladipur - Discussion

On Day 2 participants saw demonstration of PU shell filling using MF-based PU system by NVP Vladipur.

The main conclusions and recommendations of the event are as follows:

- PU system processors participating in the workshop were presented information about existing alternative ozone safe foaming agents.

- Participants familiarized with physical and chemical properties of MF as a foaming agent.

It was observed that corrosive activity of MF-based PU systems much depends on its contents in a certain formulation. The usual amount of 3–5% wt. will unlikely cause corrosion in foaming machines and dosing equipment. With increase of material processing degree, influence of aggressive media reduces.

The pilot test at NVP Vladipur showed that after processing of 2 tons of MF-based component A for production of shells of various diameters, no corrosion or damage to Henneke HK-720 high pressure filling machine processed was detected.

Final conclusions on corrosive activity of MF-based components A and need to use equipment with operating surfaces of corrosion-resistant materials should be made on the basis of a long-term research. - As PU foaming agent, MF will be used by systems house NVP Vladipur for production of components A for various needs: shells, insulation plates, including high density ones, etc.

- Supplies of pilot batches of components and tests at corporate customers’ plants are planned for January–February 2016.

- The additional study of physical and chemical properties of end products will be made after tests at corporate customers’ plants.

- Technical documentation will be developed after tests at corporate customers’ plants.

- NVP Vladipur and customers made a preliminary arrangement about fixing the price.