Project components

1. Building institutional capacity

In May, 2011, proposals on institutional capacity strengthening in state regulation of ODS and ODS-containing products in the Russian Federation were prepared, based on letters from self-regulating organizations, trade associations, equipment producers, research institutes and higher educational institutions (totally, more than 800 organizations) in response to the request of S. Korotkov, head of the UNIDO Centre for International Industrial Cooperation in the Russian Federation.

Some proposals provided the basis for instructions to federal executive agencies adopted at the session of the Russian government dedicated to the establishment of the state system for regulation of use of ozone-depleting substances and ODS-based products within the territory of the Russian Federation, June 22, 2011, minutes of the meeting No. 20. UNIDO’s experts participated in preparation to that session and in other meetings initiated by MNRE (preparation of UNIDO work plans, session of Environment protection technical committee, TK-409, etc.).

PMU members participated in the conference call of representatives of the Navy General Headquarters, MNRE, and Montreal Protocol Secretariat and involved TEAP international experts dedicated to CFC-12 exception for essential uses in the Russian Federation.

They assisted MNRE in collection of information about ODS demands of legal entities and sole traders for 2015 and participated in the offsite meeting of MNRE and Ministry of Industry and Trade of the Russian Federation dedicated to chemical and technical security of the Russian Federation (Perm, 14–15.04.2015).

PMU members consulted officials of Rosprirodnadzor (the Federal Service for Supervision in the Sphere of Nature Management) on ODS circulation control.

Draft documents and proposals for FCS were prepared and discussed with heads and representatives of FCS. These documents and proposals are related to organization of customs control over import and export of ODS and ODS-containing products in the Customs Union, creation of a Working group for FCS and UNIDO on strengthening control over ODS import and export and equipment of ODS checkpoints with instrumental control means. The created Working group discussed characteristics and contents of terms of reference for services for FCS.

On 23-24.07.2015, workshop “ODS use control in the Russian Federation” was organized for representatives of Rosprirodnadzor and FCS. Unique manual “Tools and methods for detecting ozone depleting substances” was written and printed in 3 thousand copies. It sums up the global experience in combating illegal ODS circulation, gives information about legislation of the Russian Federation and Customs Union regulating this area, key ODS producers and consumers, production and consumption of ODS in the Russian Federation, common ways of illegal ODS import and methods of handling illegal ODS after detection.

A 3 day training course “Tools and methods for detecting ozone depleting substances” was developed with respective presentations, films, and a training laboratory was equipped for training of MIA’s and FCS’s officials.

2. HFC and HCFC Life Cycle Performance Analysis

To perform the HCFC and HFC life cycle performance analysis, terms of reference were prepared, and a contract with a winning bidder, an international adviser, was signed.

Analysis of HCFC/HFC life cycle was performed for equipment installed at facilities of various scale—from industrial enterprises to international airport, — and the consolidated data and results of the analysis were integrated in the guidelines prepared by the subcontractor.

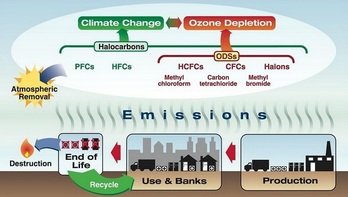

The climate change mitigation policy is being finalized and accepted by the Government. Scenarios and mechanisms of HCFC phase out may be used for HFC phase out and be adapted to developing phase out scenarios, international climate agreements and technology developments. Currently, the Russian government considers various F-gas phase out scenarios. All the Project sub-projects didn’t use both HCFC and HFC energy efficient technologies in refrigeration and air-conditioning and foam sectors of the Russian industry. These technologies demonstrated not only efficiency but high energy efficiency and commercial acceptability for the Russian market. Results of the Project implementation may lay in the basis of F-gas focused actions.

3. Phase-out of HCFC consumption in Foam and Refrigeration Sectors

Implementation of the activities listed below provided significant impact and added value to the use of environmental friendly technologies in targeted sectors in the Russian Federation. Conversion of all planned enterprises enhanced direct HCFC phase out, assisted country to meet the Montreal Protocol obligations, as crucial part of the primary project objective and ultimately increase technical capacity of the beneficiaries (enterprises) with increase of energy efficiency.

A number of enterprises were keen to assist in the pre-project research and proved the importance of this project. Thus, they participated in preparation of tender documentation, i.e. ToRs and technical specifications for process equipment for conversion to ozone-safe substances and technologies.

Conversion of the foam equipment was carried out at:

- Izolyatsiony trubny zavod (Pipe-insulation plant), Peresvet city, Moscow region;

- KZH Biryusa, Krasnoyarsk;

- Polus Company, Yoshkar-Ola;

- TPK Orskie zavody , Orsk, Orenburg region;

- Tsentrtranstekhmash, Ryazan;

- Shumerlya Plant of Purpose-built Vehicles, Shumerlya, Chuvash Republic;

- Krasnogorsk Trailer Industrial Complex, Krasnogorsk, Moscow region;

- Ariadna-Yug, Leningradskaya, Krasnodar region;

- Dow-Izolan, Vladimir;

- Vladipur, Vladimir;

- SEPO-ZEM, Saratov;

- Pozis (Sergo plant), Zelenodolsk, Tatarstan.

Conversion of manufacture of refrigeration and air-conditioning equipment was carried out at:

- Ostrov-Komplekt, Moscow region;

- KPP Nord, Moscow region.

4. Development of ODS destruction facility and supporting recovery network

Activities on establishment of the ODS-containing equipment destruction system in Russian regions and changes to regulations and standards on ODS destruction began with meetings and consultations with potential participants of the Project.

The ODS destruction facility was established on the base of LLC UKO, Dedenevo, Moscow region, the winning bidder.

The prepared recommendations on establishment of the ODS-containing equipment disposal network also included commercial sustainability recommendations which were improved and adapted by national experts.

5. Stimulating market growth for energy efficient refrigeration and air conditioning equipment, servicing sector

With participation of MNRE, leading associations and trade unions, the professional standard on ODS record keeping, leakage reduction and environmentally safe disposal was developed by 2015.

Activities to develop and approve draft interstate standard “Refrigerating Systems and Heat Pumps. Competence of Personnel” were taken.

Workshop “Establishment of the certification and accreditation system for technicians engaged in installation, maintenance and repair of refrigerating, air-conditioning equipment and heat pumps” was held to cover 4 levels of professional development programs on maintenance and servicing of refrigerating installations as well as management, training and knowledge assessment of staff.

Training and technology transfer centers were established and equipped (Vercont and Centre of Excellence), and interaction with WorldSkills started.

6. Technology Transfer

Technology transfer at KPP Nord allowed to start production of more energy efficient CO2 refrigeration systems. According to the calculations provided in the feasibility study, the improvement of energy efficiency reaches 30% (depending on the climate zone).

This part of the Project activities was supported by a workshop, “Organization of manufacture of CO2 refrigeration equipment. Working model of CO2 refrigeration plant for a retail food store” participated by representatives of the refrigeration sector.

A pilot CO2 plant developed under the Project demonstrates advantages of using CO2 in refrigeration systems and represents an option to improve energy efficiency up to 30%.

7. Integrated strategy for HCFC production closure

Report “Phase out of hydrochlorofluorocarbons production at chemical enterprises of the Russian Federation in 2013-2014 and 2015-2020” was developed and submitted to MNRE, Ministry of Industry and Trade, GK Russian Technologies, OAO GaloPolimer, VOAO Khimprom, OAO GaloPolimer Perm and OOO GaloPolimer Kirovo-Chepetsk. Cooperation agreements in principal with Russian HCFC producers were reached.

The Russian Government was submitted proposals for organization of production of ozone-safe HC and synthetic refrigerants with low GWP.

Government decree No. 228 dated 24.03.2014, inter alia, banned design (since 1.07.2014) and construction (since 1.01.2015) of any facilities used for economic or other activity where ODS or ODS-containing eqiument are produced and established available consumption volume for 2015-2019 to be equal to 399.69 ODP tonnes.

Closure of HCFC production at VOAO Khimprom allowed to reduce production by 1,840 metric tons.

Component “Institutional Capacity Building”

Institutional capacity building implies development of necessary regulatory documents, programs and action plans as well as provision of necessary support to implementation of various components of the Project, including in particular, elaboration of the Russian allocation procedure for ODS production quotas, ban on HCFCs import, establishment of record procedure for ODS use and other norms.

|

|

|

|

| The Ministry of Ecology and Natural Resources of the Russian Federation | The Ministry of Internal Affairs of the Russian Federation | The Federal Customs Service of the Russian Federation | The Federal Agency on Technical Regulating and Metrology of the Russian Federation |

Component “Technology Transfer to Russian Enterprises”

The Project provides for transmitting of advanced technologies in the foam production and refrigerating equipment manufacturing sectors. This component implies support to clean and energy efficient technologies that affect fulfilling commitments under the Montreal Protocol. Read more

Component “HCFC Phase Out in HVAC&R”

HCFC phase out in the HVAC&R sector suggests close cooperation with HVAC&R equipment manufacturers, associations, self-regulating organizations and training centers. Besides, actions on professional development of personnel engaged in maintenance and repair of HVAC&R systems will be taken. Read more

Component “Strategy for ODS Destruction and Creation of the Supporting Recovery Network”

This component is of critical importance in conditions of accelerated HCFCs phase out, since in addition to extraction of ODS, measures to environmentally safe destruction of both ODSs and equipment containing them should be taken. Read more

Component “HCFC Phase Out in the Foam Sector”

Within the framework of the Project, HCFCs used in foam production will be replaced with ozone-friendly substances. Read more

Component “Public Awareness and Stimulating of Market Growth for Energy Efficient Equipment”

Plans provide for development of new standards, printing and distribution of guidance materials, creation of the Project Internet-portal, informing at conferences of industrial units and self-regulated organizations, work with largest industry mass-media, participation in main industry exhibitions and conferences. Read more